In the vast realm of business, especially when dealing with tangible products, understanding packaging costs is pivotal. Whether you’re an established brand or a fledgling small business, being aware of where your money goes in packaging can be a game-changer.

Knowing the breakdown of packaging expenses influences decisions ranging from product pricing to marketing strategies. It not only impacts your profit margins but also how customers perceive your brand. After all, no one wants to feel they’re paying more for a product due to high packaging costs.

Diving deep into the intricacies of packaging expenses, from materials to craftsmanship, becomes a necessary endeavor for any product-driven enterprise. This guide will shed light on these costs, helping businesses navigate the complex terrain of custom packaging expenditure.

Breakdown of Packaging Costs

Every product shipped requires careful consideration of its packaging. While packaging acts as a protective measure, it’s also a brand’s initial physical touchpoint with its customers. The overall cost of packaging is shaped by multiple factors, and understanding the role of each is essential for budgeting purposes:

1. Material Costs

Cardboard & Rigid Boxes: The cost of cardboard usually depends on the grade and quality. Basic corrugated boxes are cheaper than high-grade ones. Rigid boxes, known for their sturdy nature and luxurious feel, are more expensive than standard cardboard boxes due to the quality and thickness of the material.

Other Packaging Materials: Beyond boxes, consider other materials like bubble wrap, foam, or custom inserts. Each adds a cost but enhances the product’s safety and unboxing experience.

2. Design & Printing

Graphic Design: This can be a significant cost, especially if you’re hiring an external designer. Simple designs are generally cheaper, but intricate, bespoke designs demand higher fees.

Printing: The choice between digital printing, flexographic, or litho-lamination affects costs. Color choices, print area, and finishes like gloss or matte also play a role.

3. Craftsmanship & Labor

Dedicated craftsmanship is needed for custom cuts, engravings, or special finishes. This becomes particularly relevant for luxury brands or unique packaging designs. The complexity of the box design, folding, or assembling will have associated labor costs.

4. Mold Fees

For products that need a custom shape or special design, mold fees come into play. This is a one-time investment, but it’s crucial for those looking to differentiate their products from the market.

5. Shipping & Handling

Bulkier packages or those requiring special handling can inflate shipping costs. Furthermore, where the packaging materials are sourced from can significantly affect the overall cost if they’re being shipped from overseas.

Knowing where each penny goes ensures businesses can strike a balance between cost and quality. Whether aiming for luxury or affordability, the key is informed allocation of funds.

With general costs in mind, let’s delve deeper into how specific box types can influence expenses.

Specific Costs: Cardboard Box Costs

Cardboard boxes remain one of the most common packaging solutions, especially for e-commerce and small businesses. Their versatility, recyclability, and cost-effectiveness make them a preferred choice for many. Like all packaging, their costs are multifaceted and hinge on factors such as:

- Type and Quality

- Basic corrugated boxes are economical and serve a wide array of products. These are ideal for businesses that prioritize cost-saving. Depending on the grade and quality, the price can vary significantly.

- On the other hand, high-grade cardboard, often used for premium products, costs more due to its enhanced durability and presentation.

- Size and Dimensions:

- Naturally, larger boxes command higher prices. It’s advisable for businesses to choose sizes that are a snug fit for their products to save on costs. Avoiding excessively large boxes also saves on filler materials and shipping costs.

- Naturally, larger boxes command higher prices. It’s advisable for businesses to choose sizes that are a snug fit for their products to save on costs. Avoiding excessively large boxes also saves on filler materials and shipping costs.

- Printing and Customizations:

- Basic one-color printing is more affordable than full-color, detailed prints. Brands should also factor in costs for any special finishes or coatings they desire. Add-ons like embossing or UV spot printing can increase costs but add a touch of luxury to the box.

- Basic one-color printing is more affordable than full-color, detailed prints. Brands should also factor in costs for any special finishes or coatings they desire. Add-ons like embossing or UV spot printing can increase costs but add a touch of luxury to the box.

- Volume:

- Ordering in bulk generally brings down the cost per unit. For businesses that have a predictable sales pattern, buying cardboard boxes wholesale can lead to substantial savings.

- Ordering in bulk generally brings down the cost per unit. For businesses that have a predictable sales pattern, buying cardboard boxes wholesale can lead to substantial savings.

- Shipping and Handling:

- While cardboard boxes are lightweight, their bulk can add to shipping costs. Some suppliers offer free shipping after a certain order volume, so it’s wise to inquire and possibly consolidate orders.

- While cardboard boxes are lightweight, their bulk can add to shipping costs. Some suppliers offer free shipping after a certain order volume, so it’s wise to inquire and possibly consolidate orders.

Choosing the right supplier can also influence costs. It’s prudent for businesses to seek quotations from multiple suppliers, ensuring they get competitive rates without compromising on quality.

Specific Costs: Folding Carton Box Costs

Folding cartons, commonly made from paperboard, are prevalent in retail packaging. They’re lightweight, yet sturdy enough to protect most consumer goods, ranging from cereals to cosmetics. Their costs can vary based on:

- Type and Quality:

- Folding cartons come in various grades of paperboard, with some being thin and lightweight and others being more rigid and sturdy. The type chosen can significantly influence costs. Premium or specialty paperboard materials, for instance, will come with a heftier price tag.

- Folding cartons come in various grades of paperboard, with some being thin and lightweight and others being more rigid and sturdy. The type chosen can significantly influence costs. Premium or specialty paperboard materials, for instance, will come with a heftier price tag.

- Size and Dimensions:

- Just like corrugated boxes, the size and shape of folding cartons can vary the price. Specialized shapes or sizes might require unique dies, which can add to the production cost.

- Just like corrugated boxes, the size and shape of folding cartons can vary the price. Specialized shapes or sizes might require unique dies, which can add to the production cost.

- Printing and Customizations:

- Folding cartons are known for their print quality. Full-color prints with detailed graphics are common, but they do add to the price. Special finishes such as foil stamping, lamination, or embossing can enhance the appearance but will also increase the cost.

- Folding cartons are known for their print quality. Full-color prints with detailed graphics are common, but they do add to the price. Special finishes such as foil stamping, lamination, or embossing can enhance the appearance but will also increase the cost.

- Volume:

- As with most packaging solutions, ordering in larger volumes often reduces the cost per unit. It’s beneficial for brands to forecast their needs and order in bulk when possible.

- As with most packaging solutions, ordering in larger volumes often reduces the cost per unit. It’s beneficial for brands to forecast their needs and order in bulk when possible.

- Shipping and Handling:

- Though folding cartons are relatively lightweight, the volume of an order can influence shipping costs. It’s crucial to factor in shipping when calculating overall packaging expenses, especially if ordering from international suppliers.

- Though folding cartons are relatively lightweight, the volume of an order can influence shipping costs. It’s crucial to factor in shipping when calculating overall packaging expenses, especially if ordering from international suppliers.

When selecting folding carton packaging, businesses should also consider the ease of assembly, as complicated designs might require more labor and time during the packaging process, adding to indirect costs.

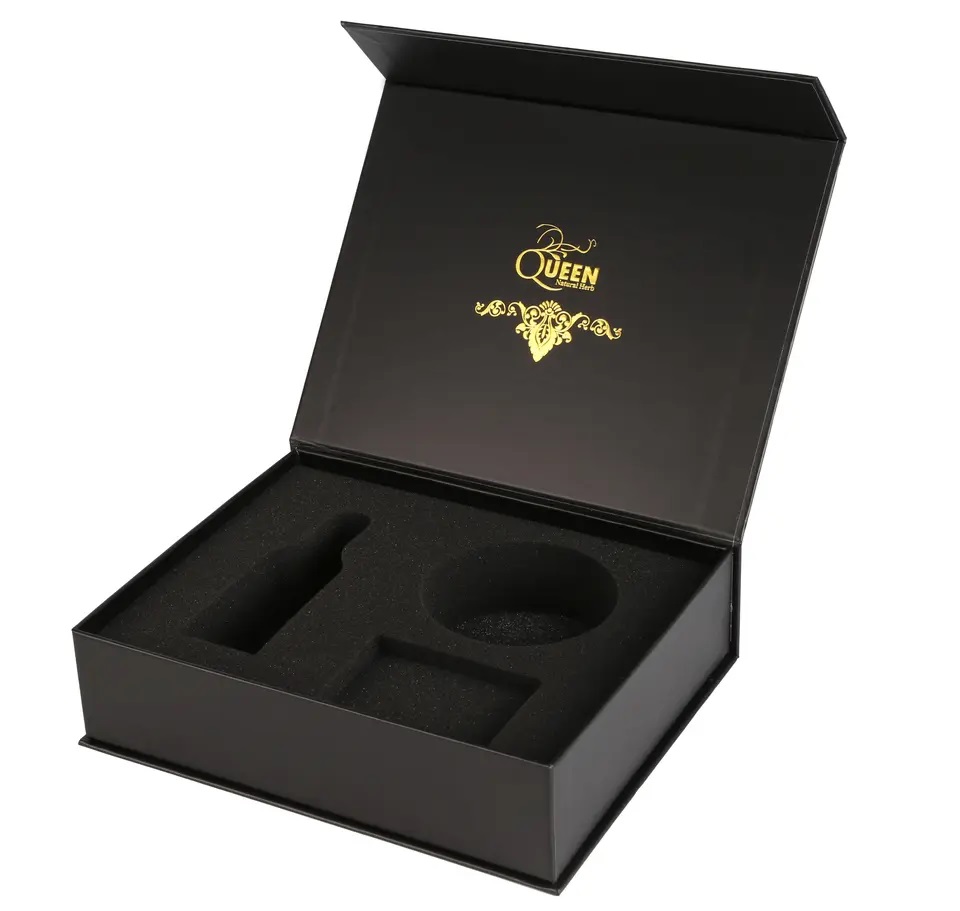

Specific Costs: Rigid Box Costs

Rigid boxes, also known as setup boxes or luxury boxes, are among the premium choices in packaging. Typically used for luxury goods, tech products, or specialty items, their sturdy construction and lavish feel come at a cost:

- Material Selection:

- The quality and type of materials used play a significant role in determining the cost. While all rigid boxes offer a sense of luxury, the choice between standard paper-wrapped chipboard or a more exotic material can make a difference in price.

- The quality and type of materials used play a significant role in determining the cost. While all rigid boxes offer a sense of luxury, the choice between standard paper-wrapped chipboard or a more exotic material can make a difference in price.

- Size and Complexity:

- The dimensions of the box, as well as any internal compartments or custom fits, can affect the price. Larger boxes or those with intricate internal designs are naturally pricier.

- The dimensions of the box, as well as any internal compartments or custom fits, can affect the price. Larger boxes or those with intricate internal designs are naturally pricier.

- Printing and Customizations:

- Rigid boxes are known for high-quality printing and can be adorned with a variety of finishes. Techniques like hot stamping, UV spot finishing, or embossing, while enhancing the luxurious feel, will add to the overall cost.

- Rigid boxes are known for high-quality printing and can be adorned with a variety of finishes. Techniques like hot stamping, UV spot finishing, or embossing, while enhancing the luxurious feel, will add to the overall cost.

- Craftsmanship and Labor:

- These boxes often require meticulous craftsmanship, which can increase production costs. Intricate designs, hand-wrapped exteriors, or hand-set embellishments can all impact the final price.

- These boxes often require meticulous craftsmanship, which can increase production costs. Intricate designs, hand-wrapped exteriors, or hand-set embellishments can all impact the final price.

- Mold and Tooling Costs:

- If your rigid box requires specialized shapes or designs, there might be an initial mold or tooling fee. While this is a one-time cost, it’s essential to spread it over the expected production volume to understand its impact on unit pricing.

- If your rigid box requires specialized shapes or designs, there might be an initial mold or tooling fee. While this is a one-time cost, it’s essential to spread it over the expected production volume to understand its impact on unit pricing.

- Volume and Order Size:

- As is the case with other types of packaging, ordering in bulk usually brings down the cost per unit. However, it’s essential to balance the savings from bulk orders against storage costs and cash flow considerations.

- As is the case with other types of packaging, ordering in bulk usually brings down the cost per unit. However, it’s essential to balance the savings from bulk orders against storage costs and cash flow considerations.

- Shipping and Storage:

- One of the primary considerations with traditional rigid boxes is their bulk and weight, which invariably leads to higher shipping costs. Their non-collapsible nature also demands more storage space. However, the advent of folding rigid boxes combines the luxury of traditional boxes with the added benefit of collapsibility. This allows for cost-effective shipping and efficient storage, reducing associated costs.

- One of the primary considerations with traditional rigid boxes is their bulk and weight, which invariably leads to higher shipping costs. Their non-collapsible nature also demands more storage space. However, the advent of folding rigid boxes combines the luxury of traditional boxes with the added benefit of collapsibility. This allows for cost-effective shipping and efficient storage, reducing associated costs.

When considering rigid boxes, it’s essential to weigh the higher costs against the perceived value they add to a product. In many cases, the premium unboxing experience they provide can justify the increased expenditure.

Conclusion

As we’ve seen, the realm of custom packaging costs is intricate. Every choice, from materials to box type, has financial ramifications. For businesses looking to dazzle with a memorable unboxing experience, understanding these costs is essential. Being informed means making decisions that boost brand value without overspending.

Looking to delve deeper into custom packaging or need expert consultation? Contact our specialists here.