Color is more than just a visual delight—it’s a branding powerhouse for your packaging. The unsung hero behind this color magic? The CMYK color model.

But what exactly is CMYK? How does it transition your designs from screen to print, ensuring a vibrant display of colors? And why is it a go-to in the printing realm?

Dive in as we unravel the essence of CMYK, explore the printing process, and discover how it can be your ally in creating packaging that resonates and stands out in a crowded market. Your journey into the heart of color printing starts here!

Understanding the CMYK Color Model

What is CMYK

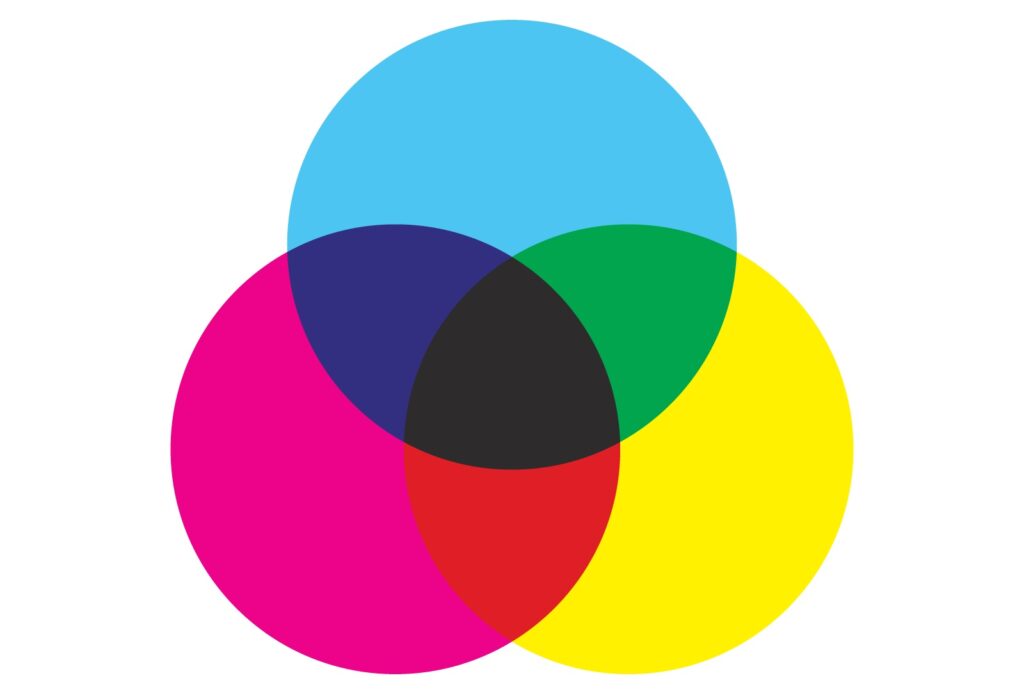

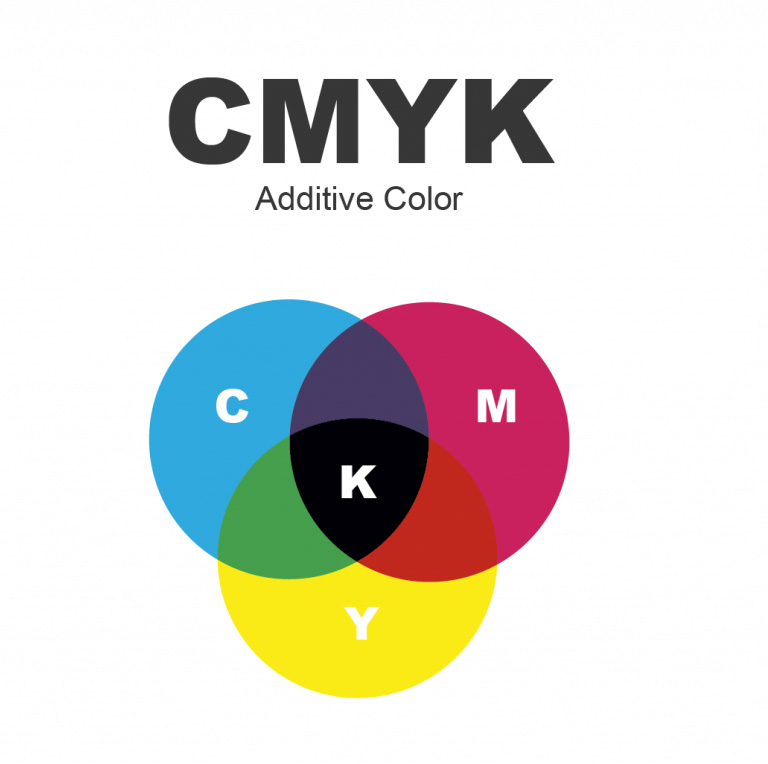

The CMYK color model, which stands for Cyan, Magenta, Yellow, and Black (Key), is a subtractive color model based on the CMY color model. It is used in color printing and describes how different colors can be produced by mixing these four ink colors together. The CMYK model works by partially or entirely masking colors on a lighter or white background. The varying degrees of the ink colors’ application will result in a wide spectrum of colors, facilitating the reproduction of a diverse range of hues and tones in printed materials.

In the CMYK color model:

Cyan: A greenish-blue color which absorbs red and reflects blue and green.

Magenta: A purplish-red color which absorbs green and reflects blue and red.

Yellow: Absorbs blue and reflects red and green.

Black (Key): Enhances the depth and contrast of the image, and is often used for outlining and text for clarity.

In subtractive color mixing, colors are created by subtracting (or absorbing) colors from white light, leaving the desired color. In the CMYK model, when colors are mixed in equal measure, they create a neutral gray or black. The more ink is added, the more colors from the white light are absorbed, and the darker the resultant color becomes. Each of the CMYK colors absorbs its complementary color from the light spectrum and reflects and transmits others, forming a vast array of colors when overlaid during the printing process.

The CMYK Printing Process

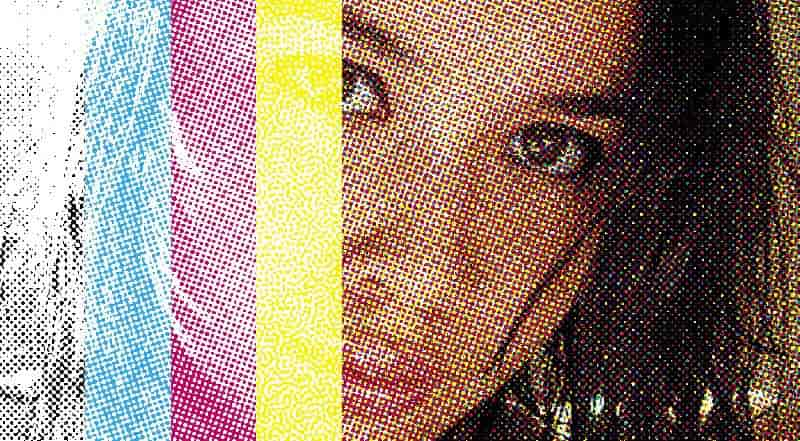

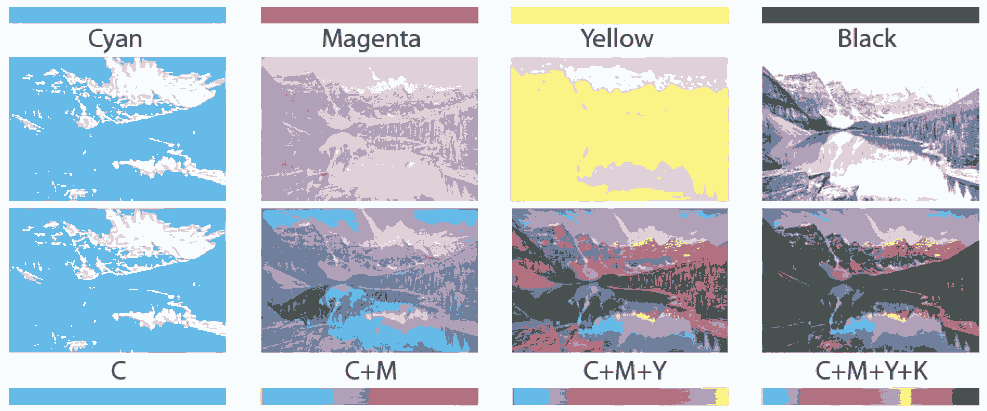

The journey from digital image to print begins with color separation, where the digital image is divided into the four CMYK color channels. Post separation, the image undergoes dot screening, converting it into varied sizes and angles for printing. The separated colors are then transferred onto printing plates.

During printing, each color is applied sequentially, overlaying inks to create a wide color spectrum. Through CMYK printing, your digital design manifests as a colorful print, true to your brand’s unique palette.

Advantages of CMYK Printing

Cost-effectiveness

Utilizing the CMYK printing process can be a cost-effective choice, especially when dealing with full-color images. The process only requires four standard inks, making it a more economical option compared to other printing methods like Pantone, which may require specialized inks.

Suitability for Full-Color Images

The CMYK printing process is ideal for printing multicolored images with a vast range of hues. Its ability to mix colors on the printing medium allows for a high degree of color variation and richness, making it suitable for photographs and complex graphics on your packaging materials.

Challenges in CMYK Printing

Color Accuracy

Achieving exact color matching can be a challenge with CMYK printing. Unlike Pantone colors that are pre-mixed to precise specifications, CMYK colors are created through a mixing process during printing, which can lead to slight variations.

Limitations in Color Gamut

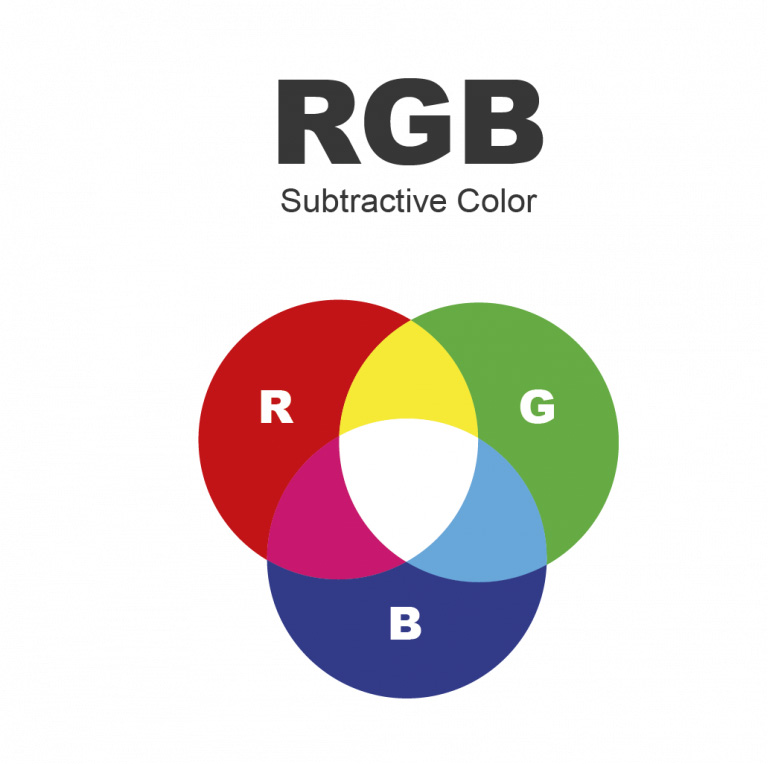

The color gamut of CMYK is narrower compared to RGB and Pantone color models. Some bright or very saturated colors achievable in RGB or Pantone systems may not be accurately reproduced using CMYK printing, which may require a compromise on color vibrancy.

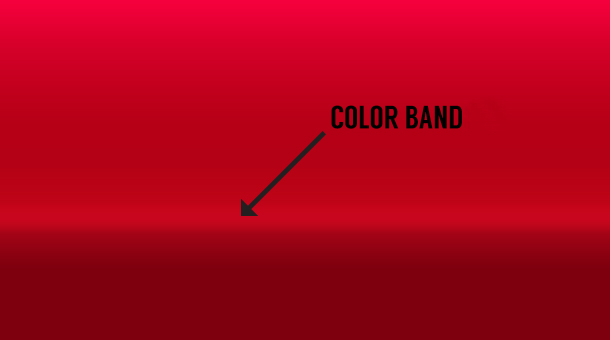

Large Solid Color Areas

Printing large areas of solid color using the CMYK model can result in banding or streaking, where uneven color or lines appear across the printed area. This is due to the mixing of the four CMYK colors which can lead to inconsistencies in color output. It’s often recommended to use spot color printing for large solid color areas to ensure a more consistent and vibrant color output. Digital printing, in particular, advises against large areas of solid CMYK mixtures for optimal results.

Tips for Effective CMYK Printing

Color Conversion Tips

When converting colors from RGB to CMYK, it’s essential to understand that the color may change due to the differences in color gamut between the two models. Utilize design software like Adobe Photoshop or Illustrator to preview and adjust colors accordingly before printing.

Ensuring Print Readiness

Double-check the resolution, file format, and color mode of your design files to ensure they are print-ready. High-resolution images and the correct file format are crucial for achieving the best printing results.

Always do a print proof before proceeding with the full print job to check for any color discrepancies or other issues.

Comparing CMYK with Other Color Models

CMYK vs RGB

| CMYK Model |

|---|

Color: Cyan, Magenta, Yellow, Black Subtractive Mixing Mix to Create Black Limited Color Possibilities Usage: Printing |

| RGB Model |

|---|

| Color: Red, Green, Blue Additive Mixing Mix to Create White Extensive Color Possibilities Usage: Printing |

CMYK vs Pantone

| CMYK Model |

|---|

| Color: Cyan, Magenta, Yellow, Black Subtractive Mixing Color Accuracy: May Have Slight Variations Limited Color Possibilities More Cost-effective Usage: Full-color Images and Photographs |

| PANTONE Model |

|---|

| Color: Various (Pantone Matching System) Pre-mixed Colors Color Accuracy: Precise Extensive Color Possibilities Higher Cost Due to Specialized Inks Usage: Brand-specific Color Matching |

Frequently Asked Questions

Get more questions on the CMYK color model and printing process? You’re not alone! Here, we’ve

1. What does CMYK stand for?

CMYK stands for Cyan, Magenta, Yellow, and Black.

2. Why do printers use CMYK instead of RGB?

RGB is an additive color model used on digital screens, where color is created by adding colored light to a black background. In the natural world, the available base color is white light. Hence, in printing, we use the subtractive color model CMYK, where color is produced by subtracting colors from white light using inks. Different colors are achieved through varying proportions of the four CMYK inks.

3. How is color separation done in CMYK printing?

Color separation in CMYK printing involves separating a colored image into four different color values (CMYK) using photo-mechanical or digital processes.

4. Why is black called key in CMYK?

Black is referred to as key because it’s essential in achieving detail and contrast in color images.

5. Can CMYK print white?

No, CMYK cannot print white. White is achieved by the absence of ink, allowing the paper’s whiteness to show through.

6. What is dot screening in CMYK printing?

Dot screening, or halftoning, is a process that simulates continuous-tone images by varying the size and spacing of tiny dots.

Conclusion

Understanding the CMYK color model and the printing process is pivotal for achieving effective and visually appealing packaging solutions. The knowledge empowers brands to make informed decisions in their printing projects, ensuring color accuracy, consistency, and cost-effectiveness. It’s about making colors work to your brand’s advantage, whether it’s through the vibrant and broad spectrum of hues achievable with CMYK or the precision and brand consistency afforded by alternative models like Pantone.

Ready to harness the power of color in your packaging?

Reach out to us for professional guidance and let’s create packaging that truly resonates with your brand and captivates your audience.