Your product is unique, and so should its packaging. The perfect fit not only protects your product but also enhances the unboxing experience for your customer. Whether you’re considering rigid boxes or folding cartons or mailing boxes, this guide is here to help you understand how to accurately determine the right size for your packaging box.

Understanding Packaging Box Dimensions

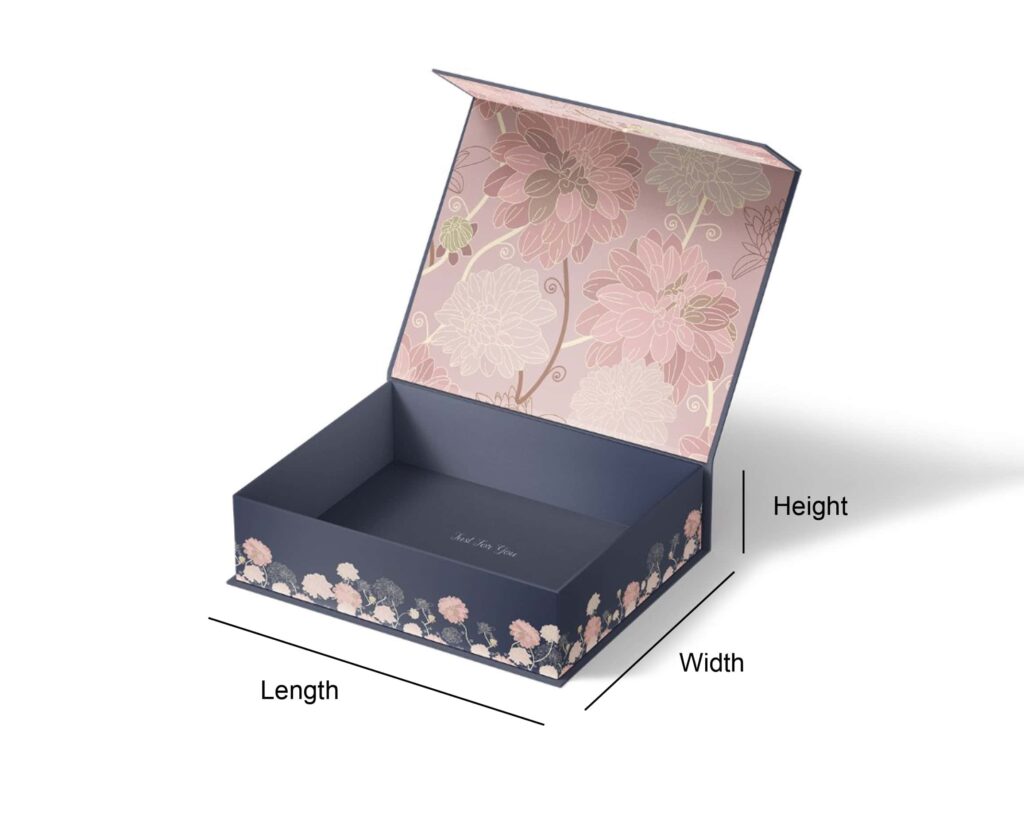

Before diving into the complexities of determining the right size for your custom packaging, let’s get a grasp on the basic concept of packaging box dimensions.

When talking about box dimensions, we refer to length, width, and height, in that specific order. For example, 300mm x 220mm x 80mm means 300mm (L) x 220mm(W) x 80mm (H)”. These dimensions refer to exterior dimensions.

- Length (L): This is the longest side of the base of the box.

- Width (W): This is the shorter side of the base of the box.

- Height (H): This is the distance from the base to the top of the box, perpendicular to the length and width.

These dimensions form the internal space of the box, which is critical for determining if your product can fit inside comfortably.

Interior and Exterior Dimensions

Furthermore, it’s essential to understand the distinction between interior and exterior dimensions. Interior dimensions refer to the usable space inside the box, while exterior dimensions are the overall size of the box, including its thickness. This understanding will ensure that your product fits properly within the box, and the box fits appropriately within the shipping or storage environment.

Key Factors to Consider for Confirming Box Size

Determining the size of your custom packaging box involves various crucial factors. These considerations directly influence how snugly your product will fit into the box and shape the overall customer experience.

Product Size

The size of your product is the most critical factor. Measure your product’s dimensions accurately to ensure it fits comfortably within the packaging box without being too tight or too loose.

When measuring your product, be aware of any protrusions or uneven surfaces. These might necessitate a little more internal space than a straightforward rectangular or square box provides.

Multiple Products in One Package

If you’re packaging multiple items together, the combined dimensions of all the items need to be taken into account. Consider how the items will be arranged within the box to ensure they fit well and present well when opened. The arrangement could be side by side, stacked, or a mix of both. Sketch out a proposed layout or think about product orientations, like keeping bottles standing upright.

You might need to include dividers or inserts to keep items separate and secure. The goal is to prevent movement that could cause damage, while also maintaining an attractive product presentation.

Protective Inserts and Cushioning

If your product is fragile or needs extra protection during transportation, factor in the space required for protective inserts like bubble wrap, foam inserts, or air pillows. This extra space is essential to consider when determining the box dimensions.

Unboxing Experience

The unboxing experience plays a crucial role in customer satisfaction. A box that’s too large may require excessive filler, which can be off-putting to customers, while a too-small box may lead to a cramped presentation of your product. Achieving the right balance in dimensions is essential for enhancing the overall customer experience and building a positive brand image.

Shipping Costs

Shipping companies often price based on dimensional weight, a pricing technique that takes into account both the size and the weight of the package. A large but lightweight package might cost more to ship than a small, heavy one. Understanding the concept of dimensional weight can help you optimize your box dimensions to minimize shipping costs.

Sustainability

Excessively large boxes can lead to wastage of material, while too small boxes may require additional protective packaging. Balancing size with sustainability can enhance your brand’s eco-friendly image.

Type of Box and Material Thickness

The thickness of your box material affects its internal dimensions. For instance, a thick-walled rigid box will have less interior space compared to a thin-walled folding carton with identical exterior dimensions. This is because the material thickness occupies a portion of the internal volume. Always consider the material thickness and box styles when calculating the internal dimensions of your packaging.

Practical Guide to Determining Your Box Size

Determining the right box size for your product requires a balance of practical considerations and strategic decision-making. Here’s a systematic approach:

1. Measure Your Product

Start by measuring your product’s length, width, and height. Consider any additional space necessary for protective padding, inserts, or any other internal components.

2. Choose the Packaging Type

Make an informed choice between a rigid box or a folding carton based on your product’s size, weight, fragility, and your brand’s image and budget. Your choice between a rigid box and a folding carton should be guided by your product’s characteristics and your brand’s requirements. Rigid boxes are often used for luxury items due to their sturdy construction and premium feel while folding cartons are versatile and cost-effective, suitable for a wide range of products.

For a deeper dive into the diverse packaging options available, explore more packaging types/styles here.

3. Add Extra Space

Remember to add a little extra space to your measurements to accommodate the thickness of the material and ensure a comfortable fit. A good rule of thumb is to add 5mm to each dimension.

4. Prototyping

After finalizing the box dimensions, consider getting a prototype of your product packaging. This allows you to test the fit, protection, and overall look and feel of your product within the package. It can also reveal if your initial dimensions need adjustments.

Conclusion

Selecting the correct dimensions for your custom packaging box is a crucial step toward creating a memorable brand experience.

At TopGiftBoxes, we understand the importance of getting it right. From the product size to the unboxing experience and sustainability concerns, we’re here to guide you through the process, ensuring your packaging perfectly fits your product and aligns with your brand.

Hope this article has given you some valuable insights into determining the perfect box size for your product. If you have any more questions, feel free to contact our specialist here. We’re always here to help!