In the world of packaging, rigid boxes stand unmatched for their durability and elegance. Made from high-quality rigid cardboard, these boxes epitomize luxury and protection.

This guide explores the universe of rigid packaging, diving into aspects such as cardboard thickness and rigid box material to different packaging box styles and beyond.

Embark on this journey to understand how these superior boxes enhance product appeal and ensure unparalleled safety.

What is Rigid Packaging?

Rigid packaging refers to packaging solutions that maintain their shape, offering a robust and durable packaging option. These non-flexible boxes are widely preferred for their strength and premium appeal.

Rigid boxes, also known as rigid set up boxes or rigid setup boxes, stand out due to their substantial cardboard thickness. Constructed from high-density paperboard, they are approximately four times thicker than the material used in conventional folding cartons. This exceptional thickness not only grants superior protection but also reinforces the box, making it especially suitable for safeguarding delicate or luxury items.

Given their robust nature and elegant presentation, rigid boxes are a favored choice for packaging high-end products, electronics, specialty foods, and more.

Types of rigid boxes

When discussing rigid boxes, it’s essential to understand the various packaging box styles that fall under this category. Rigid boxes come in numerous styles, each offering unique aesthetic and functional benefits. The primary styles include:

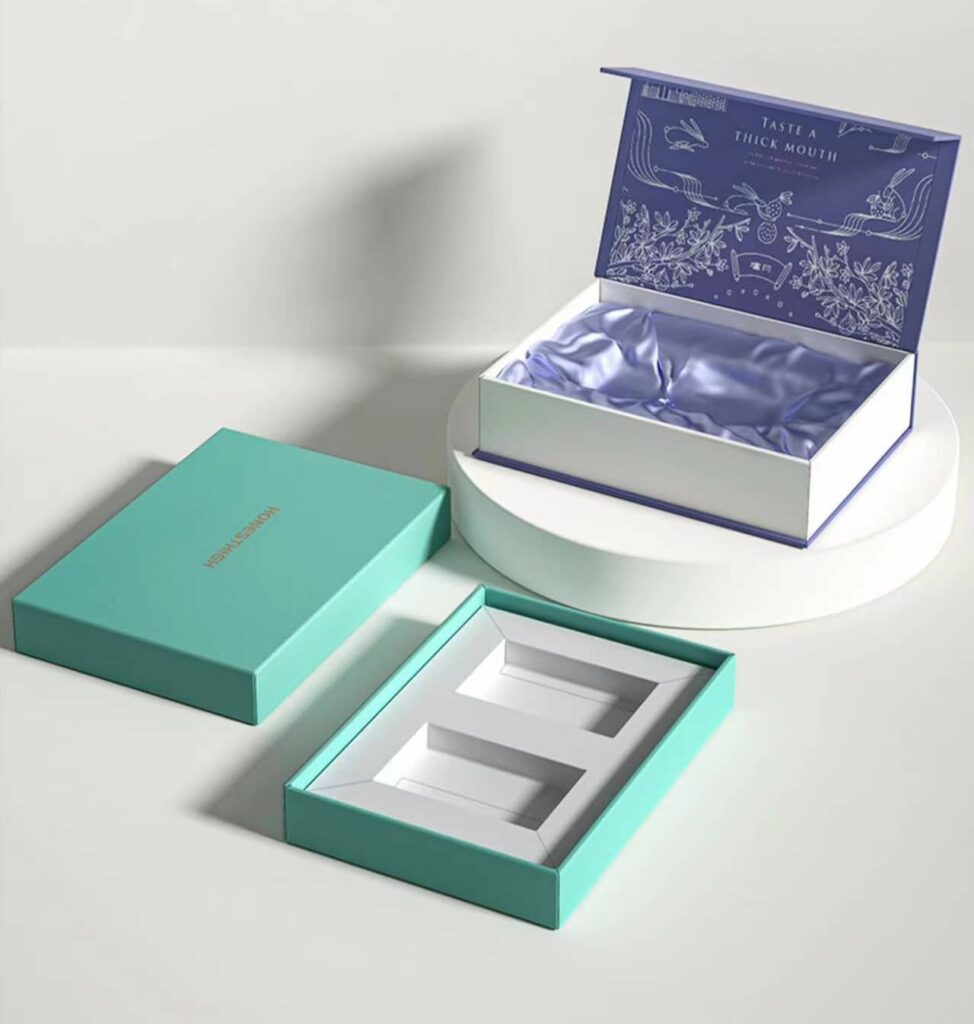

Lid and Base Box: A classic rigid paper box design, the lid and base box or the rigid boxes with lids style is frequently used for luxury packaging. It consists of two separate pieces where the base holds the product, and the lid covers it, ensuring protection and offering an elegant unboxing experience.

Hinged Lid Box: A convenient and stylish packaging option, the hinged lid box features a lid attached to the base, making it ideal for products requiring secure yet accessible packaging.

Shoulder Box: The shoulder box includes a neck or “shoulder” within the base or lid, providing additional support and a snug fit for the product within. This style is popular for rigid packaging of perfumes, watches, and other premium items.

Slide or Drawer Box: Rigid packaging also incorporates the slide or drawer box style, where the box slides out from a sleeve, offering a unique unboxing experience and added security.

Collapsible Box: For a more eco-friendly and storage-efficient option, collapsible boxes can be assembled and disassembled easily, combining the sturdiness of rigid boxes with practicality.

Round or Cylindrical Box: Perfect for products like bottles, candles, or confectionery, round or cylindrical boxes add a distinctive touch to packaging, setting the product apart on the shelves.

For a full browse of our rigid box styles, visit here.

How Rigid Boxes Are Made?

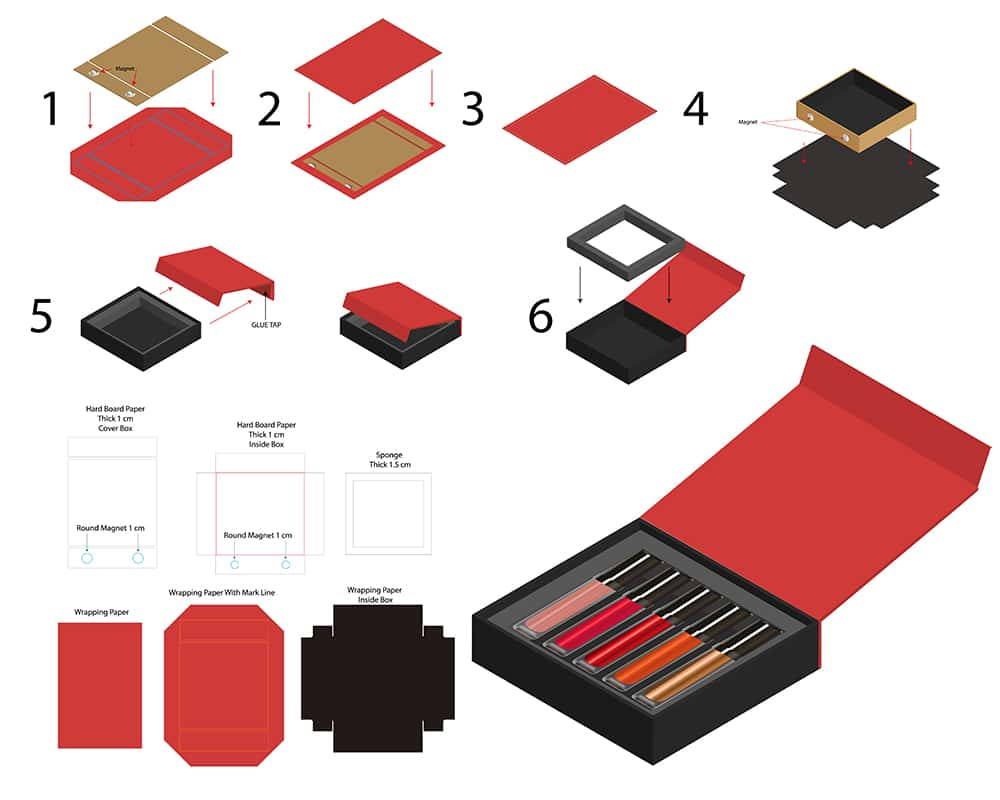

The manufacturing process of rigid boxes is more complex compared to other types of boxes. It involves several steps to ensure the cardboard thickness and other specifications meet the desired standards.

Material Preparation

The process starts with choosing the right rigid box material. High-density paperboard is commonly used, with a cardboard thickness typically ranging from 2-3.5mm. Generally, a 2mm thickness is suitable for smaller boxes housing lighter products, while 3mm is opted for larger boxes. For heavier products, a cardboard thickness of 3.5mm provides optimal robustness and protection, ensuring the integrity of the product boxes.

Cutting and Assembling

Precision cutting machinery trims the paperboard to the required dimensions. The cut pieces are then manually or mechanically assembled into the rigid cardboard structure, forming the body of the product boxes.

Covering

Post-assembly, the boxes are adorned with an outer layer, often of premium-quality paper or fabric, enhancing the box’s aesthetic appeal. This phase allows for customizations in textures, colors, and finishes, enabling brands to echo their identity through the hard box packaging.

Finishing Touches

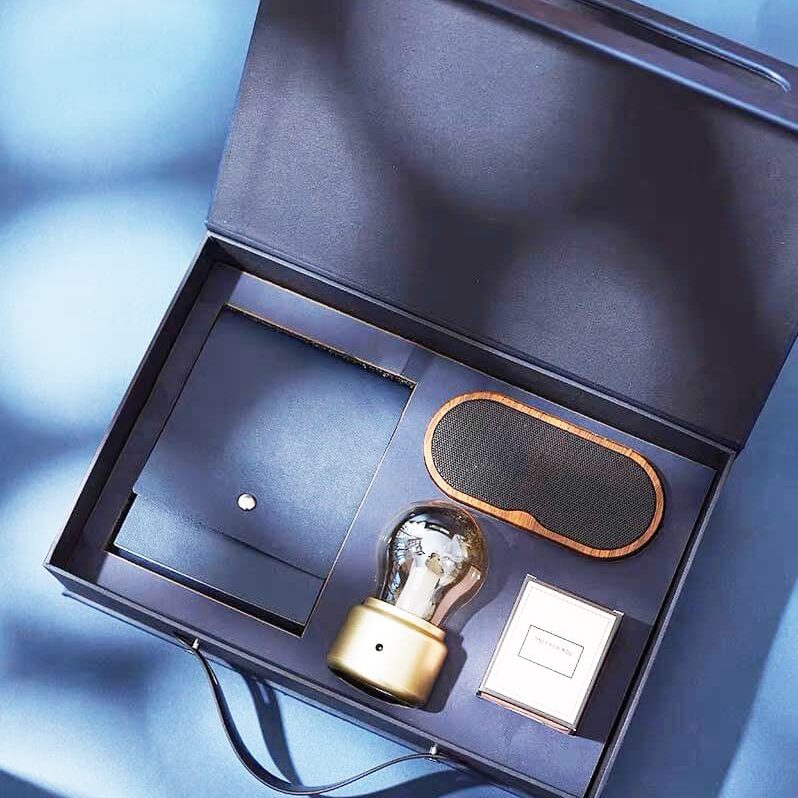

Final steps include adding any additional elements such as inserts, closures, or embellishments. This phase ensures the rigid boxes with lids, or any different types of boxes, are complete with all functional and decorative aspects, ready for product placement.

Quality Checking

Each rigid paper box is thoroughly inspected for any defects or issues, ensuring only top-quality boxes are delivered.

Advantages and Disadvantages of Rigid Packaging

In the world of packaging, rigid boxes stand out for their durability and premium appeal. However, like any other packaging solution, they have their own set of pros and cons. It’s crucial to consider these aspects to make an informed decision for your product packaging needs. Below is a quick comparison to help guide your choice:

| Advantages | Disadvantages |

| Luxury Look | Higher Cost |

| Elegant Presentation | Larger carbon footprint |

| Durable Construction | Increased shipping cost and weight |

| Versatile Styles | Limited Flexibility |

| Reusable | Long Turnaround Time |

Understanding these advantages and disadvantages will enable you to ascertain whether rigid packaging is the right choice for your product. Evaluate these points carefully to ensure the packaging complements your product while aligning with your brand values and budget constraints.

Applications of Rigid Packaging

Rigid packaging is a valuable asset in various industries, ensuring not only the protection and safety of products but also enhancing the brand’s presence and customer experience. Below are the diverse applications of rigid packaging across different sectors:

Electronics: Rigid packaging ensures the utmost protection for delicate electronic items and accessories. Customized inserts, tailored to hold specific products securely, prevent movement and potential damage, offering peace of mind that these valuable items will reach consumers in pristine condition.

Cosmetics & Fragrances: The elegance and robustness of rigid boxes elevate the unboxing experience for high-end beauty products, mirroring the quality and luxury of the items within.

Specialty Foods & Beverages: Rigid boxes preserve the quality and integrity of gourmet foods and drinks, ensuring that they remain fresh and untainted.

Watches & Jewelry: The secure and elegant nature of rigid packaging makes it an ideal choice for packaging high-value items like watches and jewelry.

Footwear & Apparel: High-end shoes and clothing are often housed in rigid boxes, reflecting the premium nature of the products and offering a luxurious customer experience.

Games & Toys: Rigid packaging ensures the safe and appealing presentation of games and toys, making them more attractive to potential buyers.

Conclusion

Rigid packaging stands out in the world of packaging, offering unmatched durability, elegance, and high-level protection for a variety of products. Understanding the ins and outs of rigid boxes, from the types to the specific cardboard thickness and applications, enables businesses to enhance their brand image and customer satisfaction.

Ready to elevate your product packaging with rigid boxes? Contact our specialists today to explore the best packaging solutions for your business.